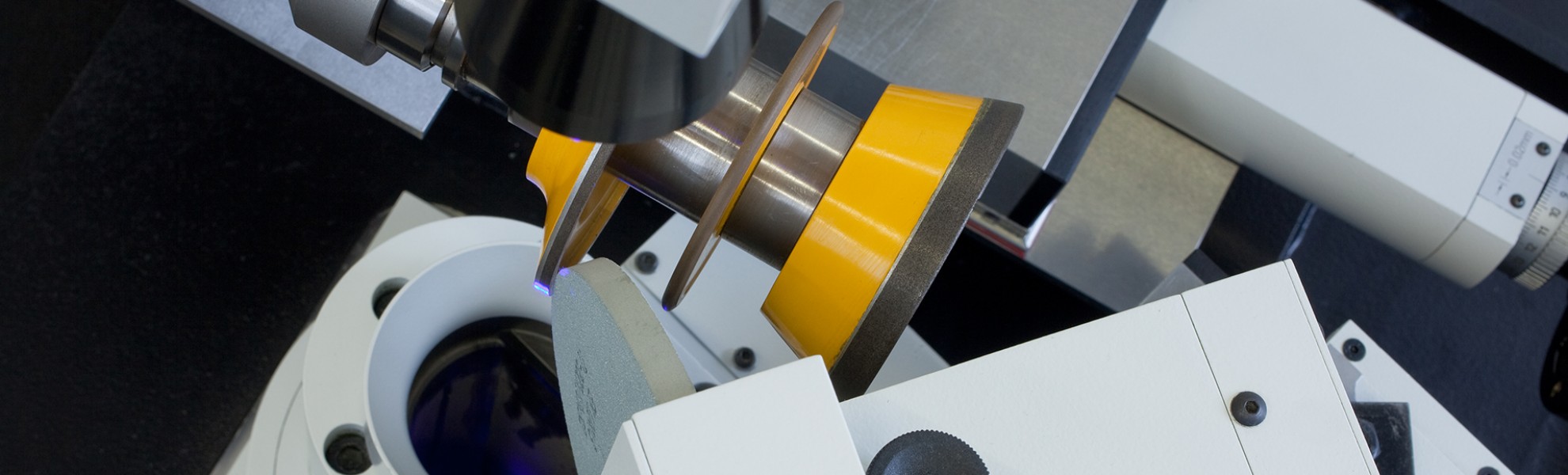

Unfortunately, due to a lack of personnel capacities with the appropriate specialist knowledge, we have to stop not only the production but also the service for our grinding machines (K360, K366) with immediate effect.

In addition, spare parts requests are only served from the existing stock. Parts not in stock will not be reordered.

We are trying to find a partner willing to take over this part of the business and who can restore service readiness as soon as possible.

Of course we very much regret this step, but due to the lack of skilled workers we do not see any alternative to this decission.

Kirner Maschinen GmbH, April 2023